Singapore – The Additive Manufacturing Innovation Centre (AMIC), in collaboration with the Advanced Manufacturing Design Centre under ST Engineering’s Commercial Aerospace business, has completed a research study focused on optimising 3D printing parameters of Stainless Steel 254 (SS254) in Singapore tailored to maritime and oil & gas applications. This project, funded by the National Additive Manufacturing Innovation Cluster (NAMIC), aims to strengthen Singapore’s capabilities in producing high-performance, additively manufactured critical components that can withstand harsh environments, such as below -50°C and above 250°C, with corrosion resistance on par with nickel superalloys.

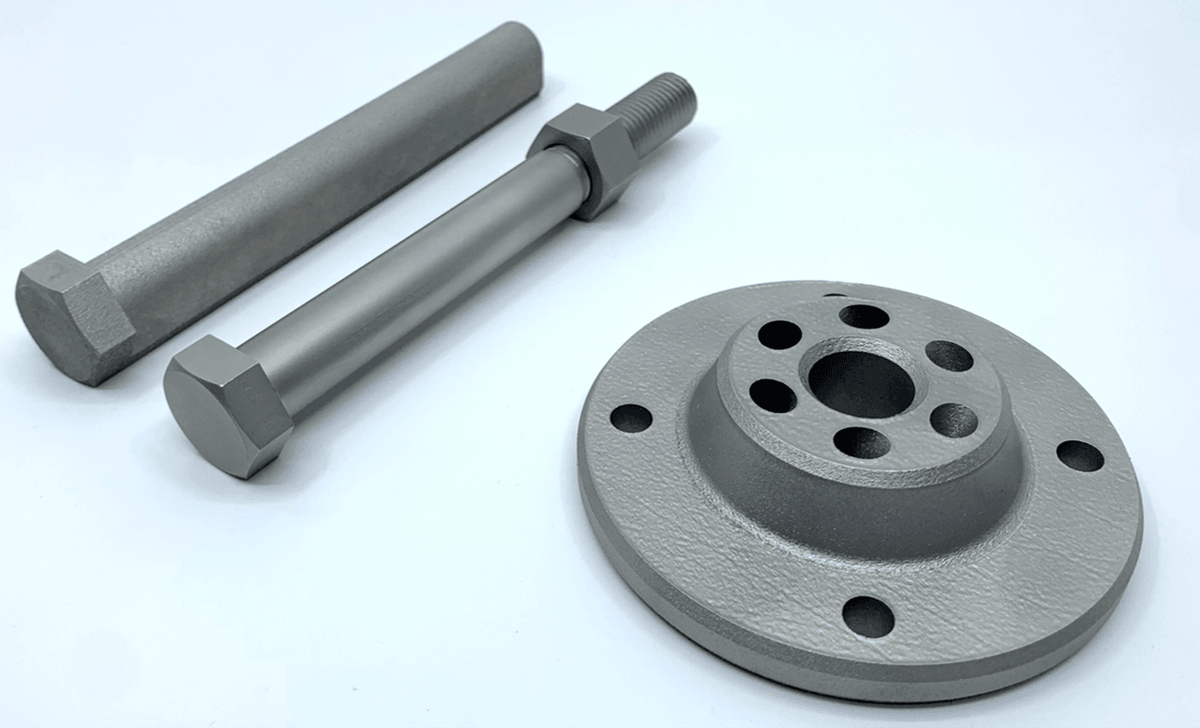

3D printed Steel 254 (SS254) parts tailored to maritime and oil & gas applications

The collaborative effort has yielded critical insights into laser powder bed fusion process parameters that influence geometry accuracy, mechanical performance, and part quality. These findings provide a valuable foundation for industrial adoption of additive manufacturing (AM) in parts of mission-critical applications such as subsea structures, ship components, and oilfield equipment.

Dr.Zheng Guoying, Head, Advanced Manufacturing Design Centre, ST Engineering, said: “This study marks a key step forward in bringing additivemanufacturing to applications under extreme environment where superior performance and high reliability is required, especially in the marine and offshore industries. By optimising and validating process parameters for the material SS254, AM solution is an effective alternative to the traditional SS254 parts with simplified material and manufacturing process as well as better consistency — paving the way forsustainable, high-performance solutions that address critical spare parts challenges faced by industry players.”

Project Highlights:

Material Focus: SS254 is a super austenitic stainless steel alloy that is known for strong corrosion resistance, particularly in saltwater, superior resistance to stress-corrosion cracking and high tensile strength. It offers a more-economic alternative to nickel and titanium alloys.

Process Optimisation: Over 5 parameter settings were evaluated on EOS M290, to identify the optimal processing window for robust part mechanical performance and quality.

Application Relevance: Results demonstrated that parts produced under the optimised parameters have met performance benchmarks relevant to maritime and oil & gas requirements. The mechanical properties are able to reach a yield strength of 600 MPa that meeting the requirements stipulated in standards such as API 6A/6D, API 5CRA, API 17F/17D, ISO 3506-1, etc.

The results of the project not only provide an evaluation of the feasibility of printing SS254 but also support the development of digital part inventories, on-demand manufacturing, and sustainable production strategies by offering an alternative cost-saving method of manufacturing SS254 for the marine offshore applications.

Looking ahead, the project partners plan to build on the findings by exploring part qualification frameworks, scaling production trials, and collaborating with end-users for field validation.

About Additive Manufacturing Innovation Centre

The Additive Manufacturing Innovation Centre (AMIC) is a Centre of Excellence for Additive Manufacturing Technology & Design Innovations set up jointly by the Singapore Economic Development Board and Nanyang Polytechnic (NYP), located in NYP. The strategic intents of AMIC are to support national AM initiatives to drive greater industry AM adoption and develop core capabilities in Design for AM optimisation and process innovation.

About ST Engineering

STEngineering is a global technology, defence and engineering group with adiverse portfolio of businesses across the aerospace, smart city, defence and public security segments. The Group harnesses technology and innovation to solve real-world problems, enabling a more secure and sustainable world. Headquartered in Singapore, it has operations spanning Asia, Europe, the Middle East and the U.S., serving customers in more than 100 countries. ST Engineering reported revenue of over $11b in FY2024 and ranks among the largest companies listed on the Singapore Exchange. It is a component stock of MSCI Singapore, FTSE Straits Times Index and Dow Jones Best-in-Class Asia Pacific Index.